Fax: 0086-523-82299306

E-mail: sales@yieto.com

Add: Economic Development Zone, Dainan Town, Xinghua, Jiangsu, China

| On Line Service : | |

Print this page Print this page |  Bookmark this Bookmark this |

Inquiry product Inquiry product |  E-mail Us E-mail Us |

Live Messenger

Live Messenger

|  PDF Download PDF Download |

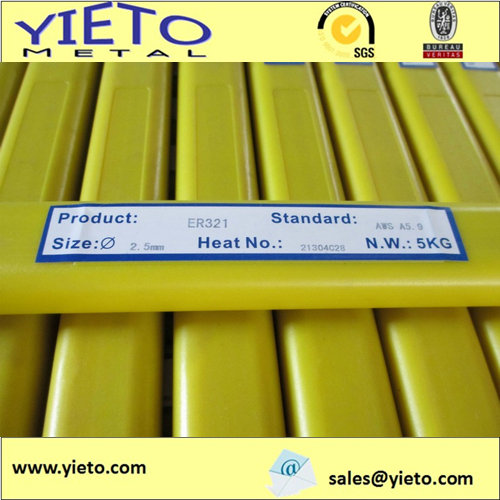

Standard: AWS A 5.9

ER 2209 is designed to weld duplex stainless steels such as 2205 (UNS Number N31803). High tensile strength and improved resistance to stress corrosion cracking and pitting characterize the welds of this wire. This wire is lower in ferrite compared to that of base metal in order to obtain improved weldability.

ER 2553 is used primarily to weld duplex stainless steels which contain approximately 25% chromium. It has a ‘duplex’ microstructure consisting of an austenite-ferrite matrix. This duplex alloy is characterized by high tensile strength, resistance to stress corrosion cracking and improved resistance to pitting.

ER 2594 is a superduplex welding wire. The Pitting Resistance Equivalent Number (PREN) is at least 40, thereby allowing the weld metal to be called a superduplex stainless steel. This welding wire provides matching chemistry and mechanical property characteristics to wrought superduplex alloys such as 2507 and Zeron 100 as well as superduplex casting alloys (ASTM A890). This welding wire is overalloyed 2-3 percent in Nickel to provide optimum ferrite/austenite ratio in the finished weld. This structure results in high tensile and yield strength along with superior resistance to SCC and pitting corrosion.

|

Wire Type |

Wire Size |

Packing |

Net Weight |

|||||||||

|

MIG Wire |

φ0.8~1.6(mm) |

D100mm D200mm D300mm D270mm |

1kg 5kg 12.5kg 15kg 20kg |

|||||||||

|

TIG Wire |

φ1.6~5.5(mm) |

1 meter/Boxes |

5kg 10kg |

|||||||||

|

Core wire |

φ1.6~5.5(mm) |

Coil or Drum |

30kg – 500kg |

|||||||||

|

Grade |

Chemical composition of welding wire (%) |

|||||||||||

|

C |

Cr |

Ni |

Mo |

Mn |

Si |

P |

S |

Cu |

N |

|||

|

ER 2209 |

0.03 |

21.5–23.5 |

7.5-9.5 |

2.5-3.5 |

0.5–2.0 |

0.9 |

0.03 |

0.03 |

0.75 |

0.08-0.2 |

||

|

ER 2553 |

0.04 |

24.0–27.0 |

4.5-6.5 |

2.9-3.9 |

1.5 |

1.0 |

0.04 |

0.03 |

1.5–2.5 |

0.1-0.25 |

||

|

ER 2594 |

0.03 |

24.0-27.0 |

8.0-10.5 |

2.5-4.5 |

2.5 |

1.0 |

0.03 |

0.02 |

1.5 |

0.2-0.3 |

||